Anodizing metal parts is a key process that has great significance in increasing the strength and life of these components. This process involves an insulating oxide to be formed on the metal parts, which exposure by immersion in electrolytic solutions. The oxide layer is being typically 5 - 25 microns thick on the surface, which plays a crucial role of toughness for the metal components in different ways.

First, the oxide layer provides a high corrosion resistance; which is beneficial for use in harsh practical applications where metal parts are subjected to weathering consistently. This ensures that these anodized metal components can battle all natural extremes from moisture, saltwaters to freezing temperature. Second, the anodized layer adds to the metal's hardness so it doesn't scratch or get as easily damaged and should last longer. Furthermore, this layer serves as an insulator to prevent potential short-circuits due to contact with other metals and increase overall safety.

This way home DIY enthusiasts can also anodize metal parts in their own home with a easy process, broken down to few short steps. On this account we must remember that for the effective performance of a task you need to have specialized gear with some specific requirements in order obtain good results.

The first step of the process is to build an electrolytic cell, a buffer that keeps the electrolytic solution and houses both cathode and anode. The anode is the portion of metal being protected, while it must be connected to another piece of conductive material (cathodic which connects with rectifier) We have created an electrolytic cell, next we will clean the metal part that need to be anodized. Either a degreaser / wire brush can be used to remove any contaminants or existing oxide layers.

After that, anodizing solution is prepared. It is ideally in a composition of 10-15% sulfuric acid with the rest being water, because Sulphuric acid and water are typically used as active ingredient. Once the solution is created, the metal parts are placed in an electrolyte solution and connected to a cathode on one side. A current is then fed into the cell, with an idealised amperage recommendation of 1-5 amps depending on power supply.

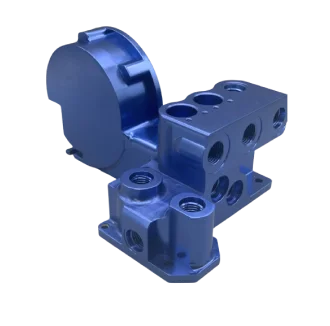

In the world of aerospace engineering, an emergent to small size component known as Metal parts Anodizing is a part and parcel process. This is largely because the conditions that affect aircraft components are incredibly harsh: high or low temperatures, starkly contrasting humidity levels and the corrosion impact of salt in seawater. For instance, you will anodize these metal pieces it is actually more of a key step in protecting against deterioration needed for metallic air-frame components (e.g., those made from aluminium) associated with the level which happens to be vunerable to possibly form or perhaps galvanic rust.

The fact that both of these panels were anodized is also indicative of the importance in the aerospace industry for some sub-components to be exceedingly reliable and last as long as possible. Anodizing is an important process in the aerospace industry as it helps to increase the wear resistance of these elements, ensuring that they function for long periods without breaking down. In addition to this, there is also the aesthetic side of things that cannot be neglected as anodizing metal parts lead to a better look which is very important within aerospace industry where professionalism and high quality are appreciated.

These are the three main methods used when anodizing metal parts, each has its own benefits which add to their suitability for different applications. Identification Solution Type Characteristics Hardcoat anodizingForms a tough oxide that provides excellent wear resistance and is ideal for parts exposed to high levels of friction. Chromic anodizing, however results in a thin but hard-wearing oxidized film that offers superb corrosion resistance, ideal for aircraft parts.

The third technique called sulfuric acid anodizing creates a thick and hard oxide layer which is most suitable for components that are subjected to severe environments due to the high wear resistant properties of this coating. Knowing the special features of each anodizing style allows people to choose the correct way in which they would take care of their metal parts.

To achienvr a sucessfull anodizing process and perfect finish, you will need to follow some rules that would be releted with the "XX do this" or"He dont doit". The objective behind these guidelines is to provide a roadmap for optimized anodizing of metal parts, reducing potential mistakes and improving the durability commonly associated with this protective process.

This highlighted that one of the Key guidelines was regular cleaning and proper surface preparation - mechanical or chemical pre-treatment, followed by degreasing prior to anodizing. Furthermore, choosing the correct anodizing process for a specific application is crucial to achieve the best possible wear and corrosion resistance with metal parts.

Also it is important for an even coating onto the surface of aluminium products in every time and fixed value current throughout the oxidizing process. On the other hand certain precautions should be followed as; metal parts are not to be touched by bare hands during anodizing does for fear of transferring either oils or contaminations that might interfere with adhesion between base and this layer (~20). Similarly, in electrolytic solutions is not appropriate to get too strong because a larger amount of gas bubbles will be formed during the process in small gaps (orange-peel effect).

To sum up: anodising metal parts of a product ensures they last longer and protect them from being damaged. For either home or aerospace use, the act of anodizing poses a variety advantages from making it corroison repellent to enhancing wear resitance and looks. Adhering to the standards and choosing between anodizing for their intended purpose allows people to prevent impediments on the functionality of various applications, while maintaining strong structural integrity throughout different uses.

Jiuding a manufacturing plant, has been anodizing metal partshigh-precision parts as well hardware accessories for over 17 years. total area exceeds 14,000 square meters. Jiuding has 3 plants warehouse satisfy all customers' requirements full time and has been more than 20 patents .

Jiuding has been accredited ISO 9001, ISO 45001, IATF 16949, and other certifications. also has over 20 patents, including bolts and anodizing metal partshardware which protected under independent intellectual property rights.

will compensate for any damage to item during transportation. The guarantee anodizing metal partswill be valid two full years following the receipt of the item.

Jiuding introduced world-class precision equipment MAZAK , MAKINO , DMG MORI , tolerance can be +-0.001mm . meet the needs of our clients make use ofvariety of machines such as CNC lathes and CNC anodizing metal partsmachines.