Here precision machining is a process of cutting and shaping material like metal or plastic into precise parts for machines and products, etc. Which we use daily. Do we actually think about the complex living mechanisms that work in unison to create things, which allow us even rooming with these s(logits) here and there? It is the world of precision machining workshops and today, we are going to explore them even further.

Know the pros of precision machining workshops

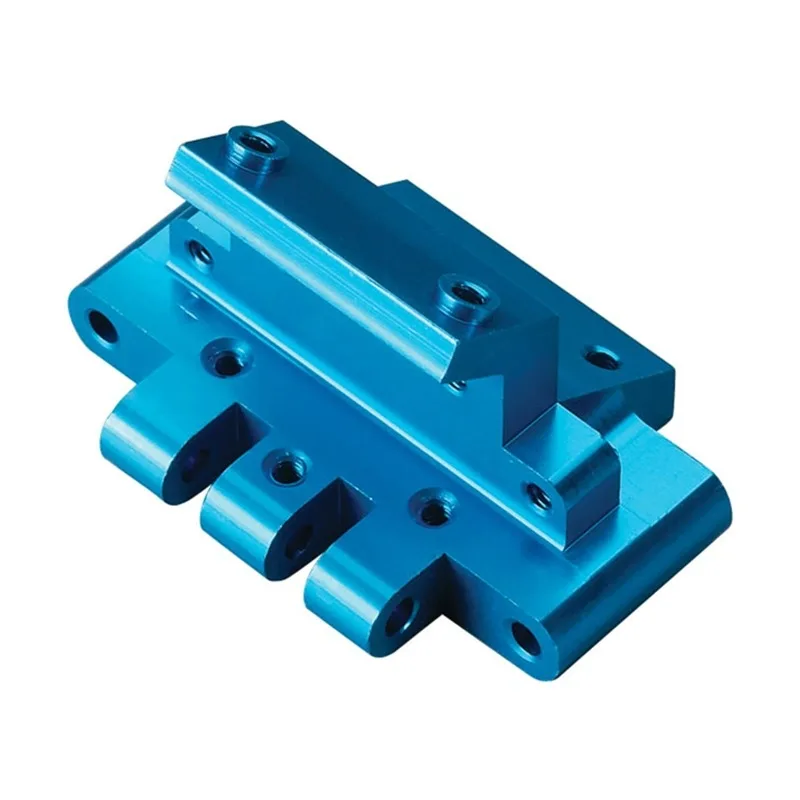

There are many benefits that precision machining workshops offer over other manufacturing methods. It allows us to produce complex shapes and dimensions in extremely high accuracy, repeatedly. This ensures that all parting is consistent with the previous divesting, making it an excellent method for shaping components which require a close fit like those of aerospace or medical devices. Moreover, 5 Axis High Precision Machining Parts are reputed for their much higher strength compared to those made from alternative processes.

Covid-19 and Precision Machining Innovation

Precision machining adopts some innovation in its part, which continues to expand and improve on the process of precision drilling and all related tasks. A crowning development has been the introduction of computer numerical control (cnc) machines which have brought unprecedented levels if automation and accuracy to precision machining. These machines are computerized to produce other parts with greater precision than can be made by man. Also, other innovative processes like additive manufacturing 3d printing) and computer-aided design(cad) have made it a vibrant field with endless opportunities to explore for Precision Machining.

Focus on Safety - Precision Machining Workshops

Safety should be the most important element of any precision machining workshop by JIUDING with managing a safe working environment for workers but also their machinery. In addition to wearing the appropriate personal protective equipment (PPE), practicing safety and using fire prevention measures, you also need other steps for keeping your workspace safe. Regular reminder for all the folks that enter the shop to not only be safe but also responsible, just in case they've magically forgot working elsewhere than a makerspace/volunteer hobby club.

Precision machining workshops made simple

The operation we are considering today is precision machining workshops, and that means building an ability to spot what the machines do so you can use them accordingly. Understanding the type of material and how accurate a part is needed for this job are also very important(assigns) workshop teams can do that within the boundaries of specific needs. Functional shape dimensions, through a detailed drawing or simple cad file resulting in a fail-safe part design for you - with workshops being used as execution houses only.

Precision Machining Workshops - Scope of Quality Requirements

The foundation of precision machining workshops is quality, resulting in the production of highest grade components according to client specifications. The belief in quality is preserved through the craftsmanship of experienced workers, choice of high-level machinery and types od material that serve varied requirements. Check gauges are used at stop 4 to validate that production remains in the "Good" end of the statistical dimension tolerance, and any damages identified.

Exclusive Uses of Precision Machining Parts

Precision machined parts have many applications across a multitude of industries, from aerospace to medical and automotive and everything in-between. Precise machined elements are necessary in aerospace to construct its gears, turbines or the structural elements that make up an aircraft. In the same way, precision machining is used in medical industries to produce pacemakers, artificial joints and surgical instruments. Precision machined parts are used in the automotive industry to manufacture a wide range of components, like valves, connectors and pistons.

Importance of Precision Machining Workshops

Precision machining workshops serve as beacons of quality and provide a comprehensive set of machines and services that have been founded to meet the demands made by different sectors. Increasing High Precision and consistency the implementation of new technologies, such as cnc machines and cad programs has not only increased precision in part production but also maximized consistency translating to higher efficiency. Safety is still at the forefront in these workshops creating a safe workshop for all personnel and kit. Inaccurate parts specifications will result in inaccurate outcomes, so it is important for part owners to have a good grasp of their specifications and work with accuracy experts on more targeted solutions. A key part of the supply chain these workshops provide a tailored precision manufacturing solution to individual machining needs and have been instrumental in the success of many industries.

Table of Contents

- Know the pros of precision machining workshops

- Covid-19 and Precision Machining Innovation

- Focus on Safety - Precision Machining Workshops

- Precision machining workshops made simple

- Precision Machining Workshops - Scope of Quality Requirements

- Exclusive Uses of Precision Machining Parts

- Importance of Precision Machining Workshops

EN

EN

/images/share.png)