CNC Milling — CNC milling is a unique way of making different parts and pieces using computer control machines. CNC is short for Computer Numerical Control, which just describes how the machine moves and cuts so precisely — a computer tells it what to do. This apparently enables the system to produce precise, speedy incisions. CNC milling is popular across various industries and can be found in businesses such as airplane construction, automobile manufacturing and even medical device making. In this field of work, everything must be done with precision and proper techniques as a slight mistake can lead to major issues.

What Is A Better Way to Understand Some Parts of CNC Milling Machine 2020?

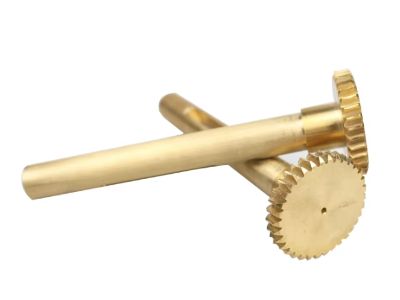

There are several important parts working in conjunction on a CNC milling machine to help make the pieces we need. The spindle is the important role among them. The spindle that the cutting tool is in and it rotates at high speeds. So by spinning, that tool can cut through things like metal or plastic. The spindle is mostly powered by an electric motor, and this keeps it working reliably.

The worktable is another crucial component of the CNC milling machine. Where the being piece cut gets placed. And moreover it is very essential to have appropriate fixture, which should in hold the work piece properly when a cutting process will perform on that. The worktable could also be repositioned, up and down or side to facet, for exact shaving. At long last the CNC Milling Parts controller, which we could liken to a brain in terms of machine. It knows what the cutter and table are supposed to do, how they should move so that everything works fine.

How to Employ CAD/CAM Software in CNC Milling

CNC milling is important part of CAD/CAM software. It has an abbreviation i. e., computer-aided CAD design. This is the type of software we use to build a highly detailed 3D model of what that part needs to be. The model reflects all details including shapes and size of the part exactly. Once the 3D model is generated in the software called CAD, another software — CAM or computer-aided manufacturing takes over. CAM Software: CAM takes that 3D model and makes it into a set of instructions the CNC controller can read. The machine can use these to precisely cut the parts, and automate much of the process that would have otherwise required human intervention.

Crucial Techniques and Tips to Keep in Mind

There are a number of important practices to follow when it comes to using Custom CNC Machining Service machines. Type of Material Being Cut (most importantly) Various materials, such as wood, metal or plastics need different cutting tools and their respective-cutting speed. The choice of tool is the thing just because it will give you better output.

Reduction of Speed/Feeds This is another major technique The machine will cut too slow or to fast, which can cause poor quality parts — and even damage the piece being worked on. Accordingly, it is crucial to strike a proper balance between the two. Coolant or other lubricants must also be used to ensure the filters of the cutting tools remain cold as they perform their function. This helps in combating overheating as it slows down the wearing life of your tools.

How to Do CNC Milling Accurate and Precisely

In order to feed precise and accuracy into CNC milling, there are some best practices which can help serve the purpose. One of the most common practices is to keep in mind that a machine must be serviced and checked for on regular basis. That includes preventative maintenance and repairing as needed so that the machine is running properly. A portion of this maintenance is done by inspecting the cutting tools for wear and changing them out as needed. Another important practice is the use of high-quality cutting tools and materials. So parts are totally manufactured with a better standard and last long.

You will also want to spend a good deal of time considering the cutting speeds and feeds. This ensure that the parts being cut are not damaged or bent while cutting. And finally, it is critical to employ CAD/CAM best practices. This means that the parts being cut are giving proper shape and this is very important to be done accurately in order tog et best results.

Last thoughts Though CNC milling is a basic procedure, it requires a high degree of precision and also accuracy Manufacturers can produce top-quality parts and components using the correct elements, CAD/CAM software, relevant techniques as well as best practices. JIUDING- Able to Achieve the Greatest Level of Precision and Quality We put the latest CNC Machining mill equipment to ensure that our customers are served with top quality products. We achieved this by focusing on what matters most, guaranteeing that every formulated part is manufactured up to the highest notch.

EN

EN

/images/share.png)