We use machine that work delicately and with precision in making something special. Turning and milling are two of the most important methods used in preparing materials into parts using CNC. These technologies are used to generate a vast amount of articles, like parts for cars and airplanes or toys we play with. Now let us delve deep into CNC turning and milling basics in this guide. JIUDING is here to help you.

What is CNC Turning?

CNC: Computer Numerical Control. So this implies that a machine which performs the turning is controlled by computer. It is a process in which we cut some material like metal; plastic trough special tool, The cutting component screwed into Spindle And Tool Starts spinning over Component. This makes CNC turning stand out because it is produced correctly by a computer. It is part of the reason why CNC turning produces accurate shapes and they come together seamlessly in other products.

What is CNC Turning And Milling?

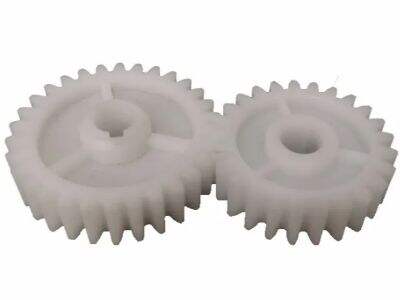

By CNC turning and CNC Milling Parts, we refer to the way in which metal (or wood or plastic) is moulded. The machine used is a lathe in CNC turning. The material spins in the machine and a tool cuts it into specific shapes. A different machine is used in CNC milling, called a milling machine. This device moves the tool in both up and down as well right to left directions while cutting material. So what is common to this machine and its cousin we discussed (EDM)? — Both machines takes out the material from job piece in a controlled manner with respect of time and produces shape which you want.

CNC Turning and Milling Step-by-Step

Just as how CNC turning takes place, so does the process of milling and Thread Locked Screw for ensuring that everything goes smooth. The first thing to do is make a design like the one above with CAD (Computer-Aided Design). That design is intended to represent the exact shape that we want our app to have. It allows us to see what the final product will look like. Once we have the design, we use a different software called CAM (Computer-Aided Manufacturing) to create a set of instructions for the machine. This program informs the machine how and with what it needs to cut.

Then, of course, we upload the program onto a machine — an essential process. The tools are then used by the machine to cut up this material as specified in our instructions. Finally, we validate that our results meet what is expected. Well, we cannot be a hundred percent sure if it does not test the application before sending to production.

Here are a few ways CNC technology can benefit manufacturing

It is all because of CNC technology that the manufacturing has become quicker, safer and more accurate ever. Using CNC technology allows extremely high detail and precision in design. We are able to traverse into these intricate shapes, which would be quite complicated or even impossible by hand. CNC (Computer Numerical Control) machines are way faster than a human and can work 24/7 without bothering for some rest. This allows us to create things faster than we could before, and speed is really important in manufacturing.

The beauty of the use of the CNC technology is that it used in safe ways as compared to traditional purposes. You don't have to concern yourself with the limitations or human error, and we can remove workers from hazardous machines as well. This makes a better and safer environment for the work implementing all those worked in making these.

Understand CNC turning and milling

A guide for CNC Turning and Milling — A few key facts you must know CAD and CAM SoftwareSince you are planning to manufacture products, the first thing that you need a command over is how CAD and CAM software works. These are the programs needed to generate machine designs and programming. The second thing is you want to read technical drawings. Technical drawings provide dimensions and details of materials. This is very useful knowledge to know about the type of work we have done.

How To Use The Machines Which in turn involves handling program loading, machine setup and right usage of controls. Finally, you must know how to examine and test the final product This is important to ensure that the product complies with all requirements and unprepared for production.

EN

EN

/images/share.png)