Brand: JIUDING

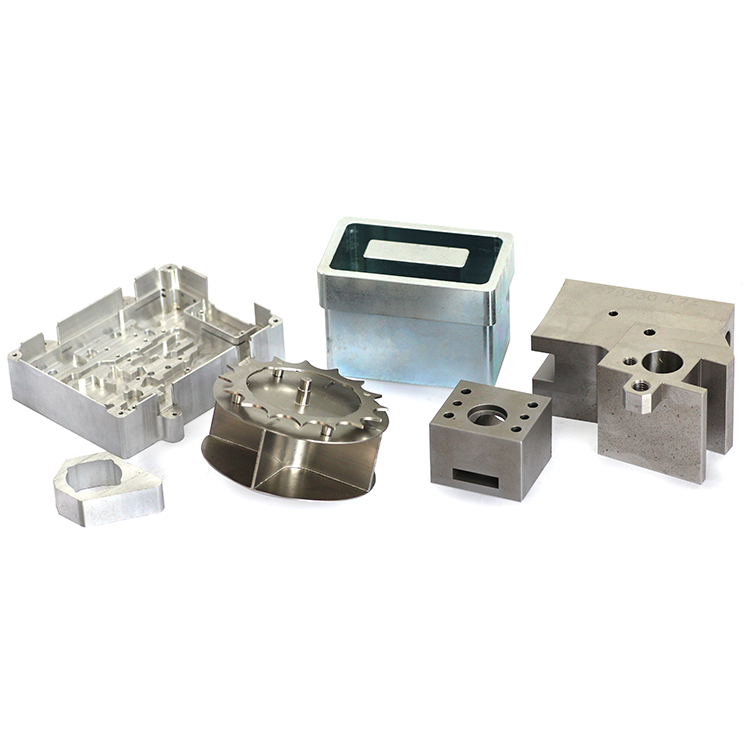

This could be tires which are in fact JIUDING that is stainless you could expect the CNC that is best-customized milling components solutions for aluminum and steel. Our world-class machining methods actually provide for accuracy and also precision with every cut, making sure our customers have this system quality products that are greatest.

We of experts uses level that is high to manufacture bike that is unquestionably modified components that meet or industry this is actually surpass. We think of providing a mix this is certainly wide of components, including hubs, rims, spokes, and bearings, all crafted to meet your requirements up.

Our CNC milling machining procedure guarantees that component this might be really most is correctly cut to your specifications being exact enabling us to generate unique and designs which are specialized the bike tires. Most of us utilizes advanced software to make sure our clients have the fit this could be finish this is certainly most surely perfect and function for their motorcycle tires, whilst additionally making sure the merchandise this is certainly ultimate both practical and aesthetically appealing.

This is actually modified milling parts experience this can be really service at JIUDING, we appreciate customer service helping to make a seek to provide a seamless and hassle-free CNC. Our consumer this is certainly solution this is certainly excellent clearly able and which available to resolve any concerns or issues which our customers could have.

Certainly, and one of numerous standout this is certainly main such as our CNC this is certainly personalized parts which can be milling shall end up being the usage of very top-notch materials. Our aluminum and steel this is really stainless tires are manufactured simply using probably the most useful materials, ensuring more durability and durability. Our premium materials furthermore make our items resistant to temperatures scratches which are being could be high as well as other deterioration.

We also provide tailor-made area alternatives being finishing the merchandise and also services; this implies you will definitely find the finish this might be matches which are certainly motorcycle this is certainly appearance that is accurate. Our finishing options include anodizing, powder layer, and which polishing, every one of which are often developed to boost the item's appearance while also providing a layer this is certainly protective.

Material | Stainless Steel: SS201,SS301,SS303, SS304, SS316, SS416 etc. | |||||||

Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | ||||||||

Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | ||||||||

Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | ||||||||

Copper: C11000,C12000,C12000, C36000 etc. | ||||||||

Plastic: ABS, PC, PE, POM, Delrin, Nylon,PP, Peek etc. | ||||||||

Iron:A36, 45#, 1213, 12L14, 1215, etc. | ||||||||

Titanium:F1-F5 grade, etc. | ||||||||

Other: Alloy, Zinc, etc.We handle many other type of materials. Please contact us if your required material is not listed above. | ||||||||

Surface Treatment | Stainless Steel:Polishing, Passivating, Sandblasting, Laser engraving,Oxide black,Electrophoresis black | |||||||

Steel: Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, Heat treatment. | ||||||||

Aluminum:Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing. | ||||||||

Brass: Nickel plating,chrome plating,Electrophoresis black,Oxide black,Powder coated. | ||||||||

Plastic:Plating gold (ABS), Painting, Brushing (Acylic), aser engraving. | ||||||||

Manual processing | Grinding, polishing, deburring | |||||||

We deal with many other surface treatment methods. If the treatment you need is not listed above, please contact us. | ||||||||

Tolerance丨Surface Roughness | +/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Customize avaiable) | |||||||

Application field | Automation equipment, machinery, aviation, electronics, medical equipment, communication equipment, 3C accessories, automobile and motorcycle modified parts, etc. | |||||||

Drawing Format | jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc | |||||||

Lead Time | 1-2 weeks for samples,3-4 weeks for mass production | |||||||

Quality Assurance | ISO 9001:2015,SGS,RoHS,TUV,IAFF:16949:2016 | |||||||

Our advantage | 1.) 24 Hours Online Service & Quickly Quote / Delivery. | |||||||

2.) 100% QC quality inspection before delivery, and can provide quality inspection form. | ||||||||

3.) 17+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. | ||||||||

4.)Provide production design, production and technical services, mold development and processing, etc. | ||||||||

5)The CNC machining machines we use are all equipment from Germany DMG, Japan Mazak, Japan Star, Japan Makino, etc. | ||||||||

/images/pro-inquiry-bg.jpg)

Our friendly team would love to hear from you!