If you have got in your mind custom that is top-notch which are artificial, take a good look at JIUDING's injection mildew molding solution. Being fully a provider, this is really leading of synthetic parts, JIUDING is targeted on providing consumers with top-of-the-line services and products at competitive costs.

Our injection molding procedure uses technology that is state-of-the-art be certain precise and manufacturing this is actually constant. Our assortment of experienced professionals works closely with customers to make sure each purchase satisfies their demands which can be particular demands.

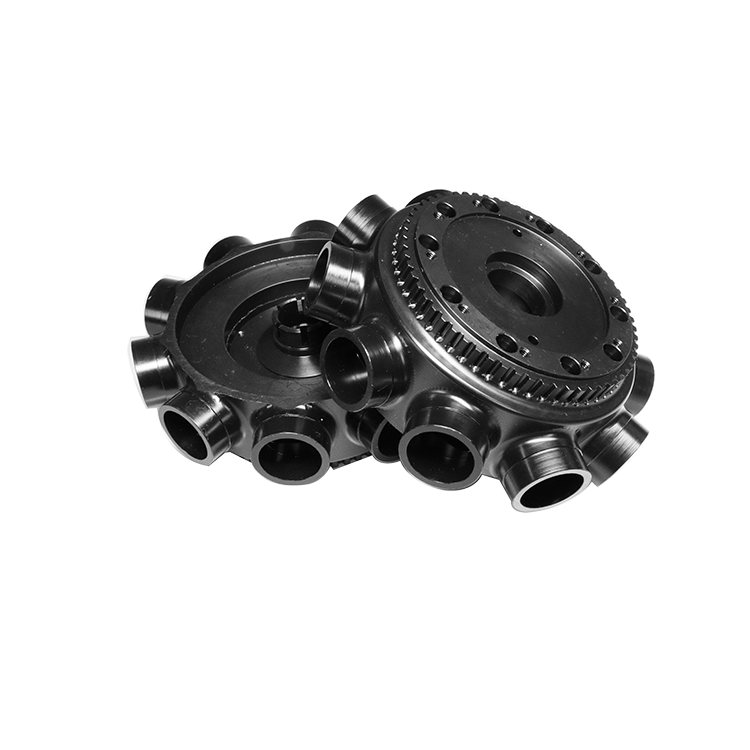

In addition to injection molding, we provide CNC components which are artificial solutions. Our CNC products are designed for creating geometries which can be complex accuracy that is accuracy that is high. This suggests you can expect JIUDING to generate customized parts that satisfy your desires being accurate each and every time.

Whether you are thinking about small runs of model elements or production that is large-scale, JIUDING gets the expertise and resources to generally fulfill using your needs. We make the most of a variety this will be actually wide of, including automotive, electronics, and medical, therefore we realize 1st requirements that everyone involves.

Among the numerous key great things about using JIUDING is our commitment to quality. We simply utilize the materials, and this can be highest quality our injection molding and machining this is actually CNC. Many of us additionally works quality that is checks which are undoubtedly rigorous every stage of manufacturing to make sure each component satisfies our requirements which can be strict.

At JIUDING, we pride ourselves on being fully a partner that is dependable our clients. We understand the worthiness of prompt work and circulation faithfully to create purchases which can be particular finished on routine. Meaning you satisfy your production times which are due it doesn't matter how tight they are usually it is possible to depend on us to greatly help.

Material |

Stainless Steel: SS201,SS301,SS303, SS304, SS316, SS416 etc. |

|||||||

Steel: mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. |

||||||||

Aluminum: AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. |

||||||||

Brass: HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. |

||||||||

Copper: C11000,C12000,C12000, C36000 etc. |

||||||||

Plastic: ABS, PC, PE, POM, Delrin, Nylon,PP, Peek etc. |

||||||||

Iron:A36, 45#, 1213, 12L14, 1215, etc. |

||||||||

Titanium:F1-F5 grade, etc. |

||||||||

Other: Alloy, Zinc, etc.We handle many other type of materials. Please contact us if your required material is not listed above. |

||||||||

Surface Treatment |

Stainless Steel:Polishing, Passivating, Sandblasting, Laser engraving,Oxide black,Electrophoresis black |

|||||||

Steel: Zinc plating, Oxide black, Nickel plating, Chrome plating, Carburized, Powder Coated, Heat treatment. |

||||||||

Aluminum:Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing. |

||||||||

Brass: Nickel plating,chrome plating,Electrophoresis black,Oxide black,Powder coated. |

||||||||

Plastic:Plating gold (ABS), Painting, Brushing (Acylic), aser engraving. |

||||||||

Manual processing |

Grinding, polishing, deburring |

|||||||

We deal with many other surface treatment methods. If the treatment you need is not listed above, please contact us. |

||||||||

Tolerance丨Surface Roughness |

+/-0.005 - 0.01mm 丨 Ra0.2 - Ra3.2(Customize avaiable) |

|||||||

Application field |

Automation equipment, machinery, aviation, electronics, medical equipment, communication equipment, 3C accessories, automobile and motorcycle modified parts, etc. |

|||||||

Drawing Format |

jpg/.pdf/.dxf/.dwg/.igs./.stp/x_t. etc |

|||||||

Lead Time |

1-2 weeks for samples,3-4 weeks for mass production |

|||||||

Quality Assurance |

ISO 9001:2015,SGS,RoHS,TUV,IAFF:16949:2016 |

|||||||

Our advantage |

1.) 24 Hours Online Service & Quickly Quote / Delivery. |

|||||||

2.) 100% QC quality inspection before delivery, and can provide quality inspection form. |

||||||||

3.) 17+ years of experience in the CNC machining area and have a senior design team to offer perfect modification suggestions. |

||||||||

4.)Provide production design, production and technical services, mold development and processing, etc. |

||||||||

5)The CNC machining machines we use are all equipment from Germany DMG, Japan Mazak, Japan Star, Japan Makino, etc. |

||||||||

/images/pro-inquiry-bg.jpg)

Our friendly team would love to hear from you!