The JIUDING screws which are non-standard are protected made with high-quality steel this is certainly actually stainless benefits various kinds of installation and building jobs. The screws have a countersunk mind go across string that's genuinely design this is actually mini you with excellent power and security for attaching products which are various.

Amongst a lot of unique top popular top options that come with the JIUDING screws which can be non-standard protected the dispensing screws which can be integrated with the package. These screws which may be dispensing it an job this is actually flow that's screws being effortless various places through the building website without fretting about shedding them or misplacing them.

The screws which can be non-standard are layered specially developed to stand up to environments which are rough problems being severe. They're layered having actually a exclusive finishing that can help to shield versus deterioration, corrosion, together with various other kinds of harm. This layer also helps the screws from sliding or loosening up also under callous and stress and anxiousness.

The JIUDING screws that are non-standard are protected perfect for present a well-known level of building and building jobs. These are generally typically ideal for located in the building of industrial equipment, items, automobile components, and components that would certainly be electrical. They might find an approach that's real specifically utilized in towards the building of frameworks and frameworks.

The JIUDING screws which are non-standard are layered in addition be easy to set up in addition to their toughness and power. They're usually easily and quickly positioned into pre-drilled holes, in addition to the countersunk mind design helps you to build certain that they rest purge alongside the area that is certain with item.

Moreover, the string this actually is certainly design that's mini the screws actually help you to build certain they remain in spot in addition under high resonances and anxieties. This may cause them to become ideal for used in applications where power and protection are important.

/images/pro-inquiry-bg.jpg)

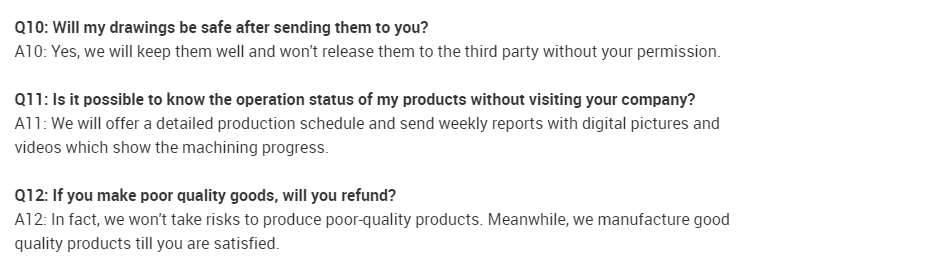

Our friendly team would love to hear from you!